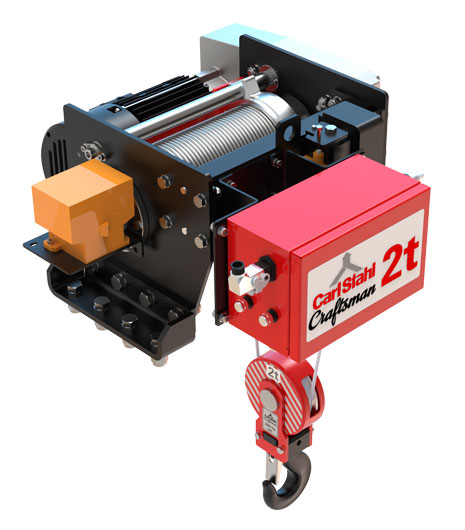

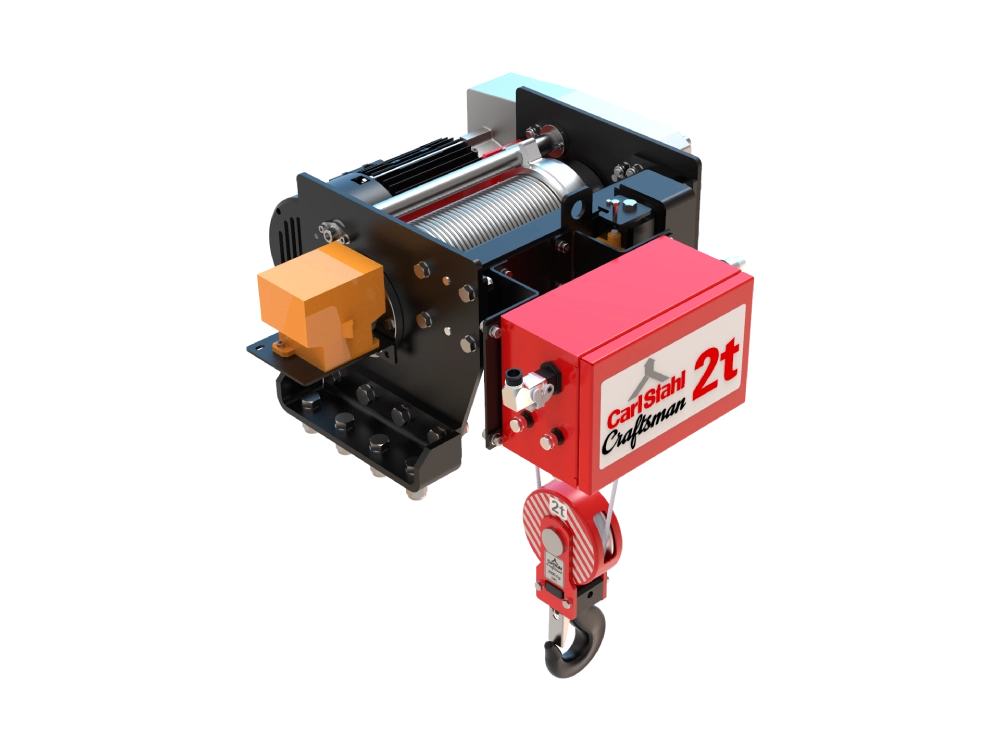

Craftsman's Fixed Hoists are reliable and adaptable solutions for diverse lifting applications

The design of our system is characterized by its compactness and an effective hook approach, ensuring efficiency in various lifting scenarios. Adhering to the M5 duty standard, the working group emphasizes reliability and high-performance operation. With dual lifting speed capabilities, the system offers flexibility in handling different loads with precision. The mounting configuration is facilitated through foot mounting, providing a fixed and stable foundation. This integrated design approach, combined with standardization in performance features, underscores the system's commitment to delivering reliable and adaptable solutions for diverse lifting applications.

Standard Specifications

| Capacity Range (Tons) | 0.5t to 1.6t |

| Classification | FEM 2m |

| Lifting Speed (m/min) | 10/2.5 , 5/1.25 ... ; Contactor Controlled |

| Travel Speed (m/min) | 25/6; Contactor Controlled |

| Power Supply | 415Volts, 3 Phase, 50 Hz, AC Supply |

| Control Supply | 48 Volts, 50 Hz, AC Supply Contactor Controlled |

| Ambient Temp.(°C) | 50°C Max |

| Application | Indoor |

| Thermal Insulation Class | F-Class |

| Motor Enclosure | IP 54 |

| Brake Type | Electromagnetic Disc Brake - DC |

| Hook | DIN 15400 |

| Rope Drum | Seamless pipe rope drum grooved as per DIN 15061 |

Fixed Hoist Models

| Model | Working Load (Tons) | Lift Height (m) | Reeving | Speed (m/mm) | FEM |

| CRU 0.5 | 0.5t | 6, 9, 12, 18, 24 | 2/1 | 2.5/10 | 2M |

| CRU 01 | 1t | 1.25/5 | |||

| CRU 02 | 1.6t |

Features

- Modular in construction with flexibility on falls interchange (4/1,2/1).

- Light weight and comparably less headroom.

- Forged hooks according to DIN standards.

- Flanged wheels to guide the runway beam.

- Travel machinery directly drives the wheels.

- Acceleration and deceleration by inverters to increase the life span of the components.

Safety

- Rope safety factor >= 5

- Motor over heating protection with thermistor.

- Double limit switch for up and down travel movement.

- Precise and accurate closed loop overload protection system (via.) VFD.

- Reliable load clamping by safety latch.

Optional Accessories

Technology

01Gear Box

02Rope Drum

03Rope Guide

04Rope

05Hook Block

06Rotary Limit Switch Equipment

07End Tie Assembly

08Panel Box

09Mounting Bracket

10Hoisting

01

Gear Box

- In-house precision machined Aluminium cast body for reduced weight.

- In-house hardened and Precision ground gears for smooth running and long life.

- Gears permanently immersed in synthetic oil for quiet, smooth and cool operation.

02

Rope Drum

- Designed for durability and life long use.

- Constructed from a high quality seamless steel.

- Manufactured according to DIN-15061.

03

Rope Guide

- Heavy duty rope guide ensures positive rope scrolling.

- GGG 40 spheroidal cast iron material used to provide low wear and keeps the rope securely in the groove on the drum.

- Special guide spring is fitted between the wire rope and the guide to maintain the correct tightness of the rope on the drum.

04

Rope

- High strength Wire Rope provides high resistance to fatigue and wear.

- Compact strand structure and highly flexible steel core rope for long life.

- High wire rope / pulley diameter ratio increases the rope life span.

- Selected according to ISO 4308-1.

05

Hook Block

- Robust design for improved safety and handling.

- Rotating hook and pulley block with safety latch.

- High strength forged steel hook capable of 360 degree rotation.

- Machined sheave grooves for long rope life.

- Designed according to DIN-15400.

06

Rotary Limit Switch Equipment

- Automatic cut-off of the lifting and lowering motions in upper and lower limit positions.

- Cut-off position can be adjusted to suit the application.

- Provides Upper/Lower motion limit switch as standard option.

07

End Tie Assembly

- Mechanical Overload protector is used as standard option to prevent lifting excessive overloads.

- Pre-set springs are mounted for rated load.

- Electronic load measure used as optional.

10

Hoisting

- Heavy duty motor with an incorporated brake and fan cooled.

- The brake disc lining material is asbestos free with high friction coefficient and long lasting.

- Provided with IP 54 enclosure rating and F insulation class.

- On request we can provided with IP55 or IP 56 enclosure rating with H Class insulation.

- Thermistors fitted on windings of the motor for protection of windings in high temperature.